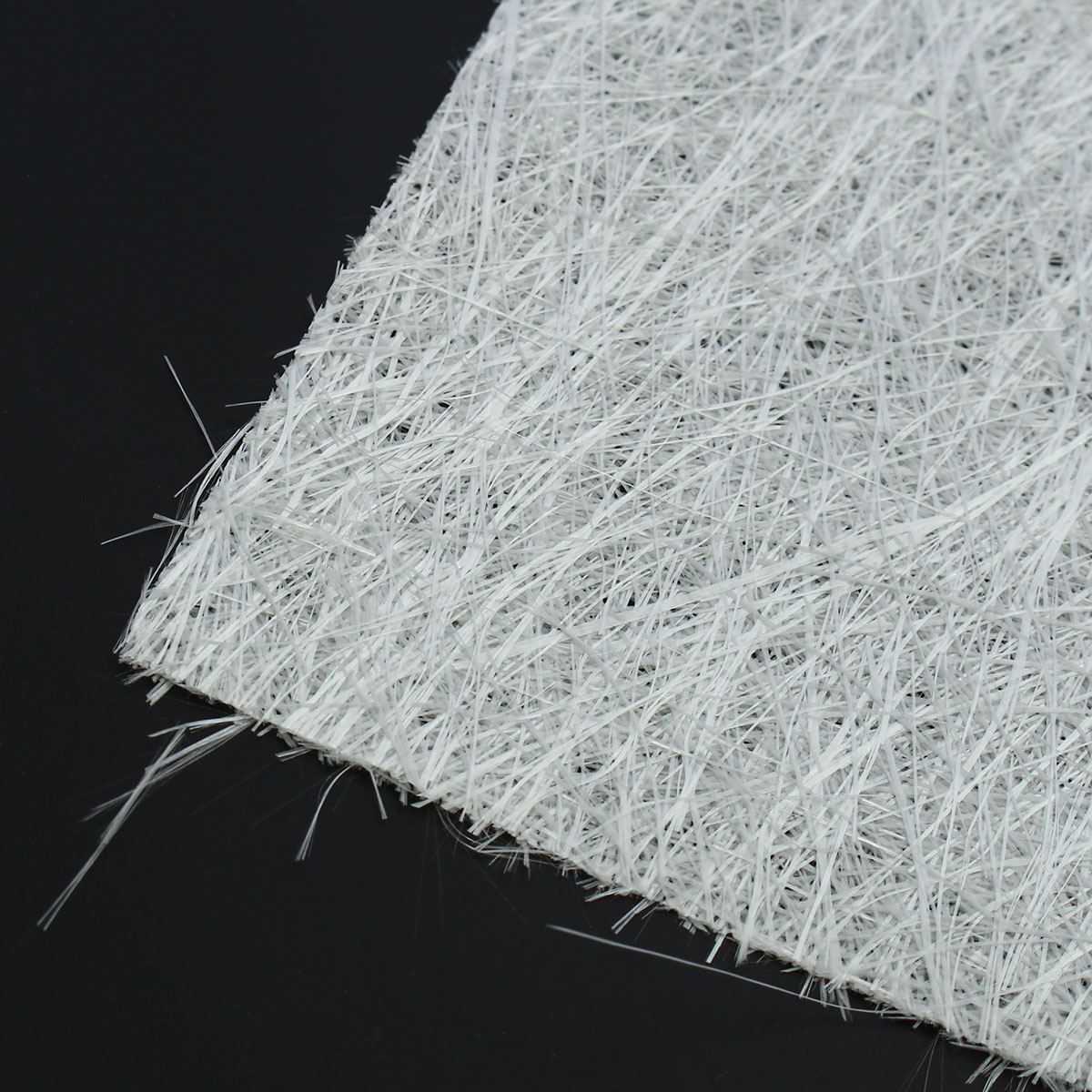

Fibre-reinforced plastic or also known as FRP, is creating an impact in service industries nowadays where the main element is fibreglass.

With its remarkable ability, people bound to use FRP instead of other materials such as another alternative for steel, aluminium, and wood for various production purposes.

As the trend is constantly changing, there are various manufacturers that begin to engage in the business of fiberglass in Malaysia.

Hence, you can easily reach out to the fiberglass supplier in Malaysia with the help of the Internet. So, what are the reason FRP has become a better alternative option over the listed material?

1. Corrosion

FRP outweighed all the other raw production material such as steel and aluminium in term of its high resistance to corrosion. FRP is highly resistant to chemicals reaction which they do not corrode easily that made it an ideal solution as fiberglass tank Malaysia.

Likewise, FRP is also waterproof and is not easily affected by the high moisture when immersed in the water. As compared to steel and aluminium, both of it is not resistant to corrosion and required constant change for the new ones.

Besides, wood-based material is not waterproof either and susceptible to the attack of the termite. Let’s take the waterslides as a real-life example.

It is not feasible to use steel or timber to produce the waterslides as they will easily rot and had low water-resistant. However, fiberglass water slides have the ability to sustain the high moisture condition and will not easily rust or rot compared to the steel.

2. Strength

With the lining and coating reinforcement to fiberglass, it has the first advantage to outweigh the other materials. First of all, it has high flexibility and volatility. FRP allows you to shape it out into various kinds of complex figures or shapes that desired.

Also, with the natural robust strength in fiberglass, this made it an ideal resource to withstand the heavyweight task and handling them easily.

Nonetheless, the flexibility of the materials like steel and aluminium is far more inferior compared to the fibreglass from FRP Trading as it requires the ponderous army to form the complex shape.

For the wood-based materials, the ability to handle the heavyweight task is relatively weak and has low volatility that made it unable to build the complex shape.

3. Weight

FRP makes a leading role in term of the load. FRP is weight at about 75% lesser than the weight of the steel, which is 30% less than the aluminium and certainly lower than timber logs.

Besides, the lighter weight is allowing you to carry the FRP faster and more at a time. Moreover, steel involves lifting equipment to carry it from one location to other locations due to its high density and weight among all.

Although aluminium and wood are lighter than the steel, it still requires more human resources to carry it. For example, home furniture. If the furniture is made of steel, aluminium or wood, it will be heavy and hard to carry around the house.

Nonetheless, fiberglass furniture is much lighter compared to these materials where you can move the furniture freely and easily around the house without fuss.

4. Electrical conductivity

FRP is a great insulator which doesn’t conduct electricity. It is much safer as compared to other materials as the FRP is prevented from the electrical waves flow that to prevent you from being by electric.

Next, steel and aluminium are a good conductor that will conduct electricity easily where you should mind on your safety from being electrocuted.

Therefore, the best material that used to design the water pool is likely to be fiberglass. This is because fiberglass pool is an efficient insulator and highly water-resistant. Besides, it doesn’t rust easily as other substances like woods and steel.

5. Colour

FRP as well as taking the lead in term of the colour. FRP doesn’t necessitate depict as the colours that are moulded during the manufacturing process and doesn’t require to repaint the fiberglass regularly.

But, materials like steel, aluminium, and wood-based are required to refurbish again overtime to ensure that the materials are still durable.

Hereby, there is another cost incurred here as it has to constantly refurbish those materials in order to prolong its long-lasting effect and durability.

Next, is the custom-made sculpture which made from the fiberglass. One of the benefits of using the fiberglass Malaysia for sculpture is because of the ability to form the complex shape easily. Furthermore, FRP has the colour moulded that able to increase the appeal of the custom-made sculpture.